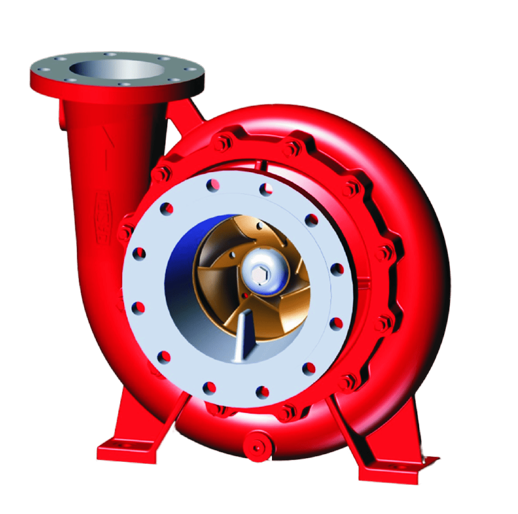

Centrifugal Fire Pumps

- Split Case End Suction Pumps

- Gear Box Pumps

- Split Case End Suction Pumps

- Complete unit responsibility.

- Complete in house fabrication capabilities.

- Hydrostatic strength testing facilities.

- Driver electric motor drive or diesel engine drive.

- Electrical testing capabilities for motors and controllers Capable to supply single skid mounted fire pump set

Pump Casing:

This casing is axially split, which permits removal of the complete rotor without moving either piping or motor. Pumps generating high heads have double volutes to reduce radial forces, ensuring minimal shaft de? ection and low bearing loads. Replaceable wear rings protect the casing the impeller running clearances.

Impellers:

The closed impellers have double curved vanes. The double suction design gives practically zero axial forces. Each impeller is dynamically balance according to ISO 1940-1 standard.

Bearings:

On both sides grease lubricated deep grove ball bearings, sealed for life.

Shaft Seal:

Soft-packed shufi ing box, cooling lines are provided for additional cooling of the graphite impregnated type gland packing

Materials:

Ductile iron casing, Bronze impeller, wear ring, shaft sleeve and Shaft in 316 SS.

| Sr. No. | Pump Model | Pressure (PSI) | FM/UL Required Pressure (PSI) | Rated Speed | Suction Intel Dia (inch) | Discharge Outlet Dia (inch) | Stage (S) |

|---|---|---|---|---|---|---|---|

| 1 | VCE 1000 | 130 | 1000 GPM | 2900 | 4 | 3 | 1 |

| 2 | VCE 1000 A | 202 | 1000 GPM | 2900 | 4 | 3 | 1 |

| Sr. No. | Pump Model | Pressure (PSI) | Flow Capacity | Rated Speed | Suction Intel Dia (inch) | Discharge Outlet Dia (inch) | Stage (S) |

|---|---|---|---|---|---|---|---|

| 1 | VCE 750 | 130 | 750 GPM | 2900 | 4 | 3 | 1 |

| 2 | VCE 750 A | 202 | 750 GPM | 2900 | 4 | 3 | 1 |

| Sr. No. | Pump Model | Pressure (PSI) | Flow Capacity | Rated Speed | Suction Intel Dia (inch) | Discharge Outlet Dia (inch) | Stage (S) |

|---|---|---|---|---|---|---|---|

| 1 | VCE 500 | 90-141 | 500 GPM | 2900 | 3 | 2.5 | 1 |

| 2 | VCE 500 A | 133-211 | 500 GPM | 2900 | 3 | 2.5 | 1 |